How to Choose the Right Welded Wire Mesh for Your Project?

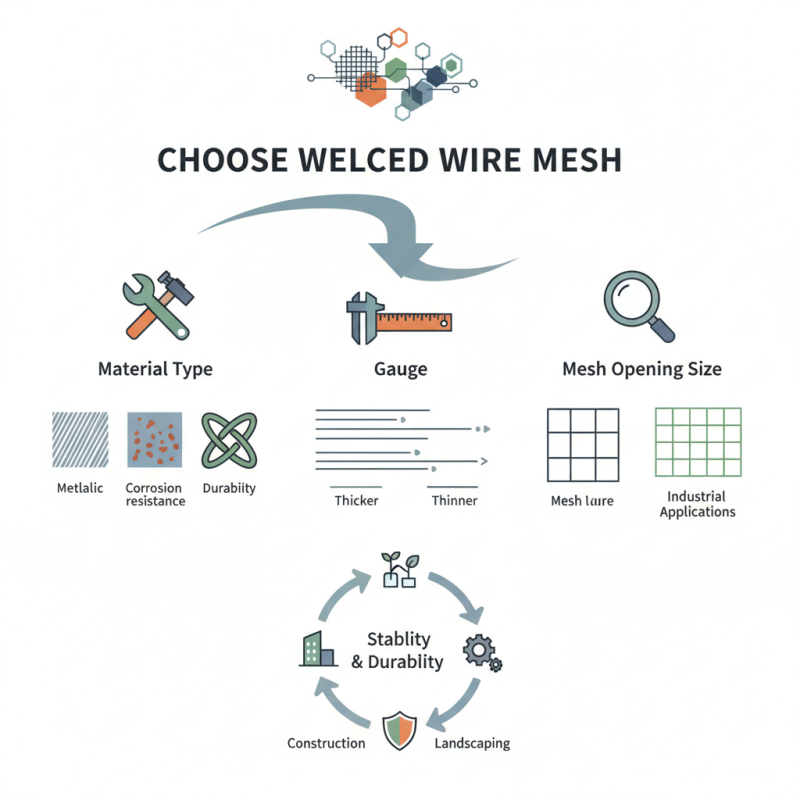

Choosing the right welded wire mesh for your project can be challenging. There are many factors to consider, including material type, gauge, and mesh opening size. According to a report by the Wire Mesh Manufacturers Association, the demand for welded wire mesh is projected to grow by 6.5% annually over the next five years. This statistic underscores the material's importance in various applications, from construction to landscaping.

Industry expert John Smith notes, "Selecting the right welded wire mesh can significantly affect your project's success." This insight reminds us that the mesh’s attributes impact stability and durability. It’s crucial to acknowledge that not every mesh suits every application. For instance, using a lighter gauge in high-stress areas may lead to failure.

Specific projects may require unique considerations, such as corrosion resistance or load-bearing capabilities. The nuances of welded wire mesh can often go unnoticed. Considering these details ensures you make the best choice for your requirements.

Understanding the Different Types of Welded Wire Mesh Available

When selecting welded wire mesh, understanding the various types available is crucial. There are different materials, sizes, and mesh configurations. Common types include galvanized wire mesh, stainless steel mesh, and PVC-coated options. Each has unique features and benefits. For example, galvanized mesh offers good corrosion resistance, while stainless steel is ideal for high-stress environments.

In 2021, the global welded wire mesh market was valued at approximately $3.4 billion and is projected to grow. This growth indicates the importance of welded wire mesh across industries like construction, agriculture, and manufacturing. Choosing the right type can significantly impact your project's success, particularly regarding durability and aesthetics.

It's essential to consider the environment where the mesh will be used. For outdoor applications, rust-resistant options are advisable. On the other hand, indoor use may not require such stringent protection. Reflecting on these details is necessary. Neglecting to select the appropriate wire mesh could lead to structural failures or increased costs over time.

How to Choose the Right Welded Wire Mesh for Your Project? - Understanding the Different Types of Welded Wire Mesh Available

| Type of Welded Wire Mesh | Wire Diameter (mm) | Mesh Size (mm) | Usage | Common Applications |

| Light Duty Welded Wire Mesh | 1.0 - 2.0 | 25 x 25 | General Use | Garden fencing, animal enclosures |

| Medium Duty Welded Wire Mesh | 2.0 - 3.0 | 50 x 50 | Structural Support | Machine guards, window protection |

| Heavy Duty Welded Wire Mesh | 3.0 - 5.0 | 100 x 100 | High Strength | Reinforcement in concrete, industrial fencing |

| Stainless Steel Welded Wire Mesh | 1.5 - 3.0 | 25 x 25 | Corrosion Resistant | Food processing, chemical industries |

Identifying the Key Factors for Selecting Welded Wire Mesh

When selecting welded wire mesh for your project, consider several key factors. The mesh's gauge determines its strength and flexibility. Thicker wires offer more durability. This choice impacts how well the mesh can withstand pressure and external forces. Make sure to evaluate your project's specific needs before deciding.

The spacing between the wires is also crucial. Wider gaps can reduce weight but may not provide enough support for certain applications. Thin spacings offer better stability but can be heavier and less cost-effective. Analyze what level of support you require.

Tips: Always measure your project area carefully. This ensures the mesh fits correctly. Think about where and how you'll use the mesh too. Environmental factors can influence its longevity. Reflect on whether you need additional coating for protection. Testing different samples can provide clarity. Remember, your decision should suit your unique project requirements.

How to Choose the Right Welded Wire Mesh for Your Project?

This chart represents the different factors to consider when selecting welded wire mesh for your project, including material type, wire diameter, mesh opening size, and expected load-bearing capacity.

Evaluating the Specifications and Strength Requirements for Your Project

When evaluating specifications for welded wire mesh, start with the project’s requirements. Identify the intended use. Is it for fencing, reinforcement, or concrete support? Each application requires different strengths and mesh sizes. Consider the load the mesh will bear. Heavy-duty projects need stronger materials.

The gauge of the wire plays a crucial role. Thicker wires can withstand more stress and tension. However, they may be heavier and harder to handle. A mesh with a small opening may not provide the airflow you need. Adjust based on your situation.

Don’t overlook environmental factors. Will the mesh be exposed to weather, chemicals, or extreme temperatures? Corrosion-resistant options might be necessary in such cases. Reflect on your choices. Sometimes, the cheapest option may lead to more costs down the line. Balancing budget and performance is vital for success. Make informed decisions to avoid regret later.

Considering Corrosion Resistance and Coating Options for Durability

When selecting welded wire mesh, corrosion resistance is key. Determine where your mesh will be used. For outdoor applications, exposure to moisture and chemicals is a concern. Look for materials that resist rust and wear. Stainless steel is often considered, but it’s not always the most budget-friendly option. Coated wire mesh provides a protective layer. Options like vinyl or epoxy coatings can enhance durability.

In addition to corrosion resistance, consider the specifics of your project. The gauge of the wire impacts strength and flexibility. Thicker wires offer greater strength but are heavier and more challenging to work with. Think about how much load the mesh will bear. Would a lighter gauge suffice? Sometimes, it’s easy to overlook these factors in the excitement of the project.

While strong and durable, welded wire mesh can pose some challenges. Coatings may wear off over time, which can lead to unforeseen rust issues. Regular maintenance checks can help, but not everyone thinks ahead. Reflect on your needs as the project progresses. Should you choose a different option down the line? Making informed decisions early can save headaches later.

Assessing Cost-Effectiveness: Budgeting for Your Welded Wire Mesh Needs

When assessing cost-effectiveness for your welded wire mesh needs, consider the overall budget. Establish your project's limits early on. This can prevent overspending and allow for other necessary materials. Exact measurements and requirements will help you avoid purchasing excess materials.

Tips: Always account for unexpected expenses. Some projects may require more mesh than anticipated. Leave a little room in your budget for these surprises.

Research different sources to find competitive pricing. Different suppliers offer various products that might meet your needs without breaking the bank. Pay attention to the gauge and spacing. A higher gauge may cost more but could offer better durability.

Evaluate the lifespan of your chosen mesh. Cheaper options may seem attractive, but they could lead to higher long-term costs. Look for reviews or ask for references. Weigh the pros and cons of each option carefully. Sometimes, saving a bit on initial costs can result in more frequent repairs or replacements.